Helping You Get New Products to Market

Good Design, Good Engineering, Good Products

We’re an engineering company and we specialize in product design

Our engineers have a combined total of over 100 years of experience designing mechanical components, hydraulic systems, hydrostatic transmissions, and sheetmetal.

Founded by Jess Davis in 1999, Davis Precision Design makes experienced engineers and designers available to manufacturers who need to develop and bring to market new products that are tough, durable, and easy to manufacture and, most importantly, easy to sell.

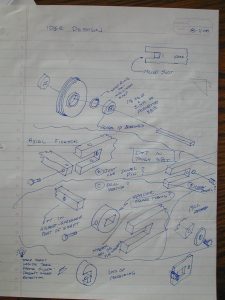

Brainstorming

So you’ve identified a problem that your customers have? Need to figure out the solution? We can help.

Let us run your brainstorming sessions. We have lots of experience and can help bring your sales staff, your engineering, and your shop guys together so their ideas can flow. An “outside” moderator is sometimes just the thing to get everyone together on neutral turf, help them focus on the right questions and bring out the best ideas for discussion.

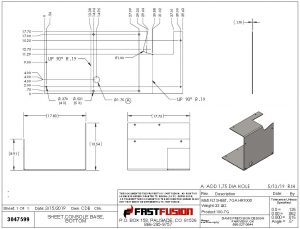

Design and Engineering

Mechanical Design of machinery is our specialty. We have 20 years of experience designing mechanical components, hydraulic systems, hydrostatic transmissions, and sheetmetal.

If you know what you need, but simply don’t have the engineering manpower to get all of your #1 priority projects accomplished, we can help. We’ll take your concepts and turn them into detail CAD models and finished drawings ready for shop release.

If you’ve got a problem and just need a solution, we can sit down with your salesmen, engineers, and customers and come up with a workable concept, then take that concept all the way to a sellable product that your customers will love.

Reverse Engineering

Sometimes the best way to develop a new product is in the shop and in the field–fabricate, cut, weld, and modify until it works. We can take your one-off hand-built test machine and use it as the basis for a professional design complete with drawings, manufacturing procedures, and parts breakdowns.

This approach allows your experienced crew to focus on the basics–making a machine that addresses your customer’s needs. They can work fast if they don’t have to worry about manufacturing processes, appearance, sourcing of production parts, and the fine-detail work that really belongs in the production design. We can take your proof-of-concept test machine and make it production-ready while your skunk works creates the next product.